Speaking of the production process of backpacks, many people may think that the production process of backpacks and clothes is similar, after all, sewing machines are used for both. In fact, this idea is wrong. There is a considerable difference between the process of backpack and clothing. In contrast, the production process of backpacks is much more complicated than that of clothes. Don’t talk nonsense, I will give you a minute to take you through the backpack production process.

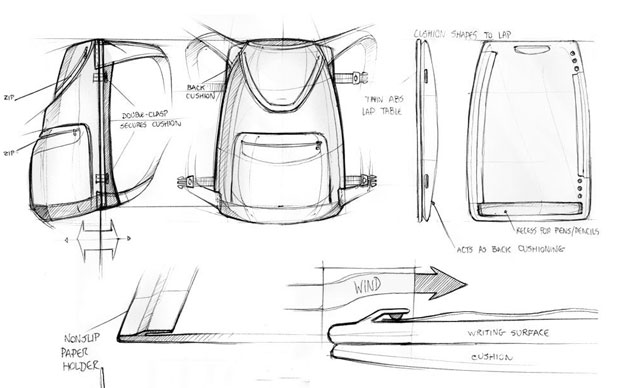

A backpack has unique craftsmanship and unchangeable process from design to forming. Every process in the production process will affect the quality of the backpack. Generally speaking, the production process of the backpack includes various processes such as material selection, sample proofing, sample setting, material preparation, die cutting, material cutting, material printing, sewing, and packaging. A backpack is usually assembled from dozens or even hundreds of parts, and the complexity of its production is self-evident.

Sewing is the most important process in the backpack production process, which directly affects the workmanship quality of the entire backpack. Sewing is further divided into sewing front piece, sewing ring, sewing lining, filling material sewing, sewing side pocket, sewing accessories, assembly accessories, installation slider, sewing back piece, high-car integrated package Wait, every process is very important. Designing a special backpack even requires the use of some special processes, such as skinning, compounding, oil edging, gluing, rivets, drawing boards, spraying, etc. If you want to make a high-quality backpack, you must strictly control every process.

Everyone knows that when producing customized backpacks, choosing a good factory can guarantee the quality of the backpack. Leishuo luggage is a luggage enterprise integrating design, production and sales. It designs customized and OEM OEM for major enterprises across the country. The production process is complete, quality assurance, and trustworthy!